Laser precision for your customized solutions: Kubo is your expert for high end laser cutting and engraving of elastomers and plastics.

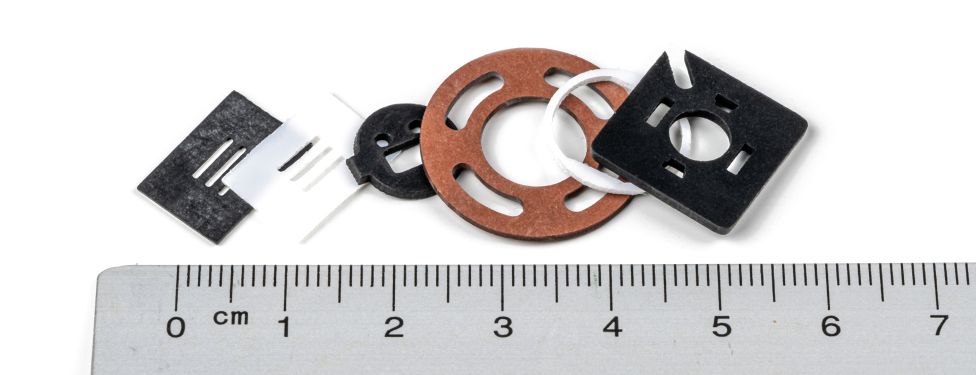

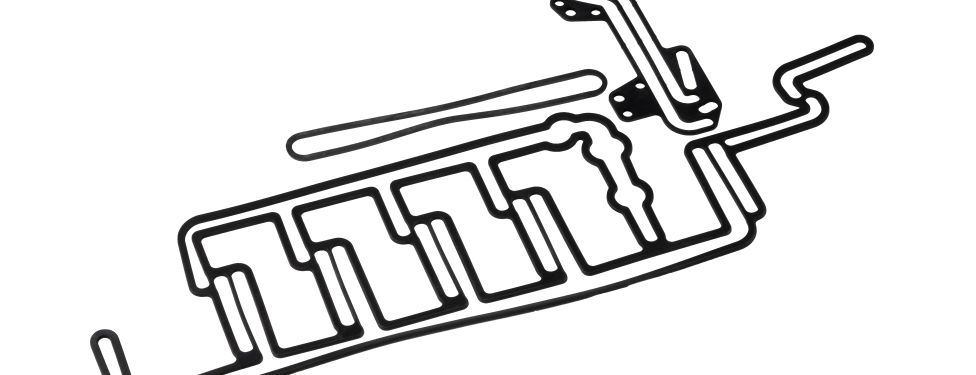

The manufacturing of technicals parts by means of laser cutting is technically demanding. Kubo is your competent partner for this process. We offer individual and highly efficient solutions, especially appropriate for sample parts, prototypes or also for serial production.

For the unique, forgery-proof, durable and economical identification of gaskets, seals and turned parts, laser engraving is the ideal process.

Kubo is your partner for laser cutting and laser engraving. Our proven expertise allows us to find the right solution for your application.

We work with a CO2 -laser device model VLS 4.75S.

Contact us to discuss your project: technik@kubo.ch.